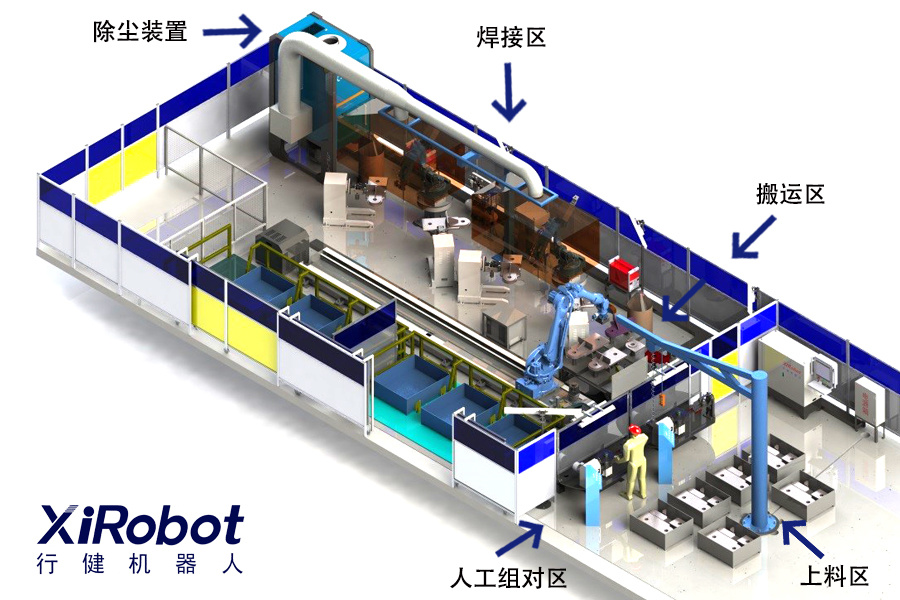

Category

Contact us

Address: No. 16 Lingyuan Road, National Robot Industrial Park, Jiujiang District, Wuhu City

Tel: +86-553-3865881

Email: xirobot@xirobot.com

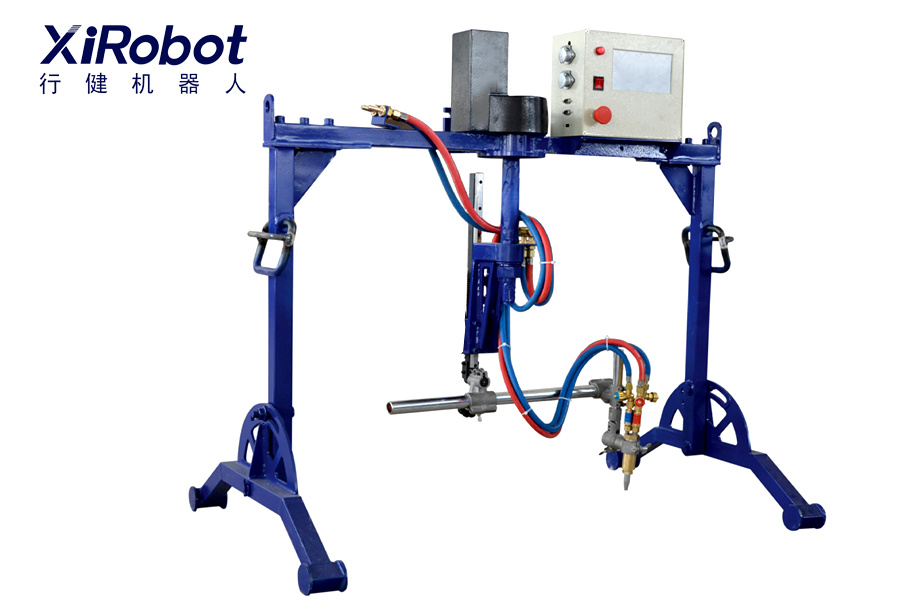

Portable saddle cutting machine

This product is a portable flame cutting equipment, which can cut holes on cylindrical shells and ellipsoidal heads, and can cut single and double sided bevels at fixed angles. It can be carried manually, mounted on the shell to be cut, or hung on the operator. It is used in chemical pressure vessels, power station boilers, nuclear power equipment, food and pharmaceutical equipment, shipbuilding and marine engineering, national defense industry and other industries.

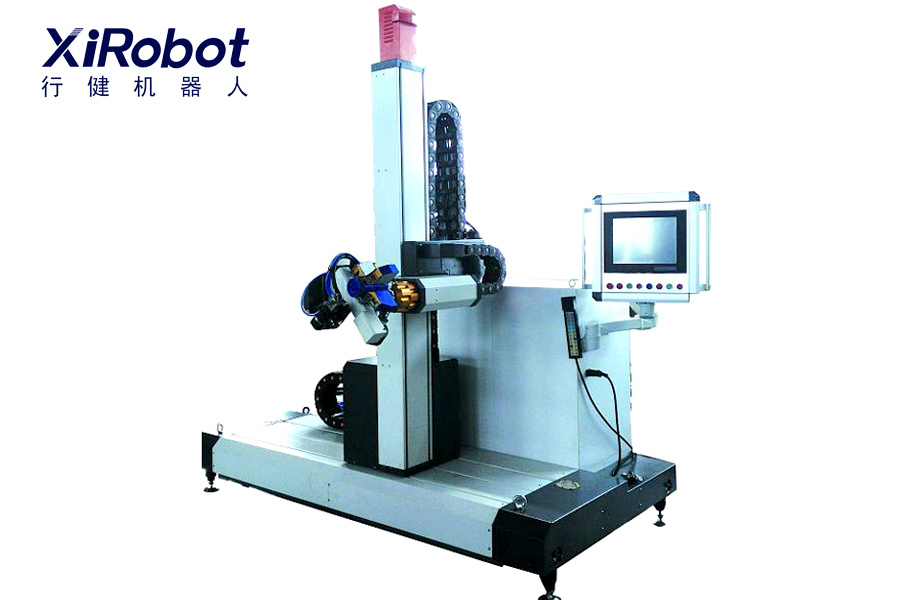

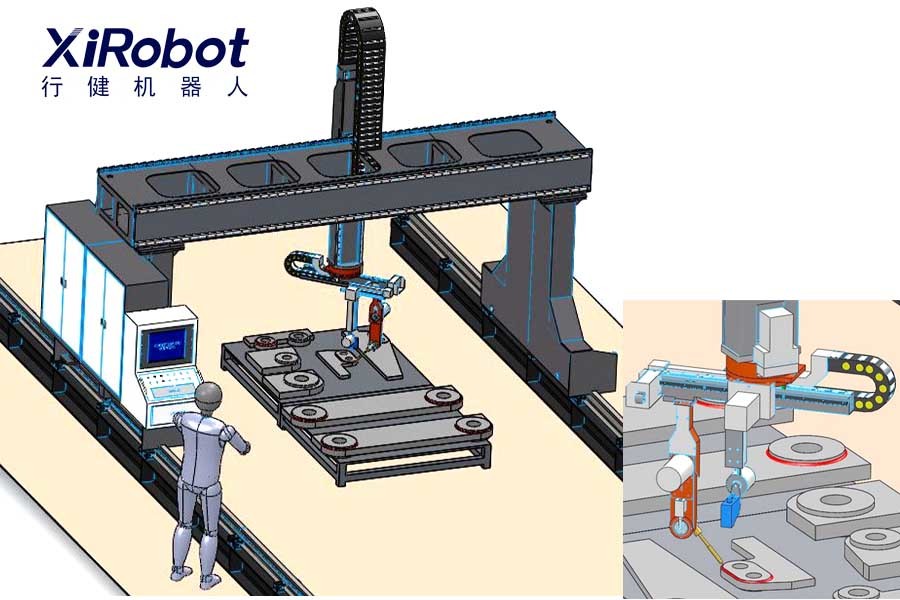

Full automatic pipe expanding robot

The special machine of the equipment is a self-propelled rectangular coordinate robot, which can walk back and forth and turn to adapt to cylinders of different lengths when placed on the ground, and can automatically level and align with the plate surface. It is mainly used for the automatic expansion of the tube sheet of the tube sheet heat exchanger. The general robot form of the equipment is 6-axis articulated arm robot. It is used in air conditioning and refrigeration, chemical pressure vessels, power station boilers, nuclear power equipment, food and pharmaceutical equipment, shipbuilding and marine engineering, national defense industry and other industries.

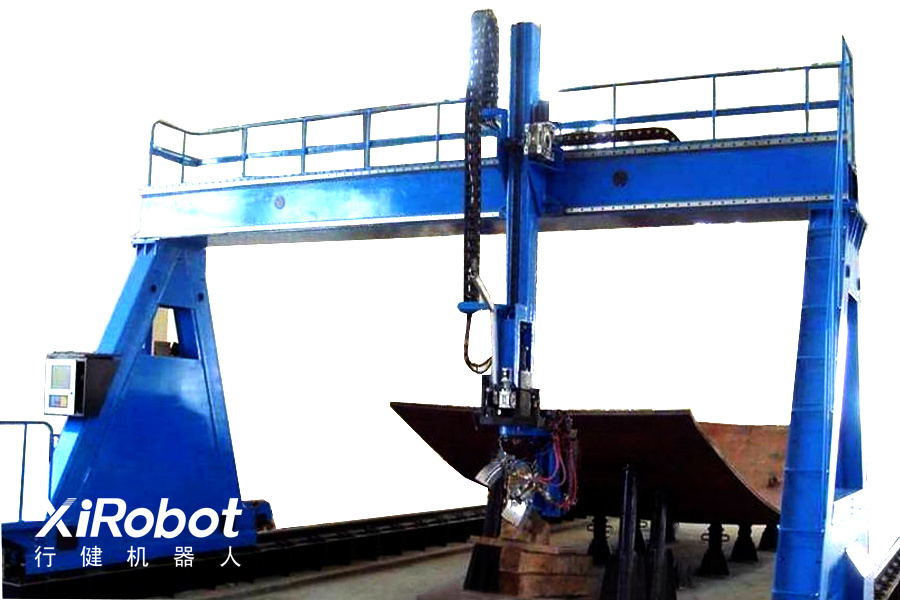

Welding robot for plate heat exchanger

This equipment is mainly used for φ The spiral weld of "flanging type" and "clamping type" spiral plate heat exchanger below 3000 shall be welded. Good weld quality and beautiful molding.

This equipment is suitable for measuring, scribing and secondary accurate cutting of spherical, ellipsoidal, conical, butterfly and other shapes of head pieces, and can directly cut out variable angle double-sided groove with double guns. It is suitable for rapid, batch and high-precision blanking of large-scale, multi curvature head pieces.

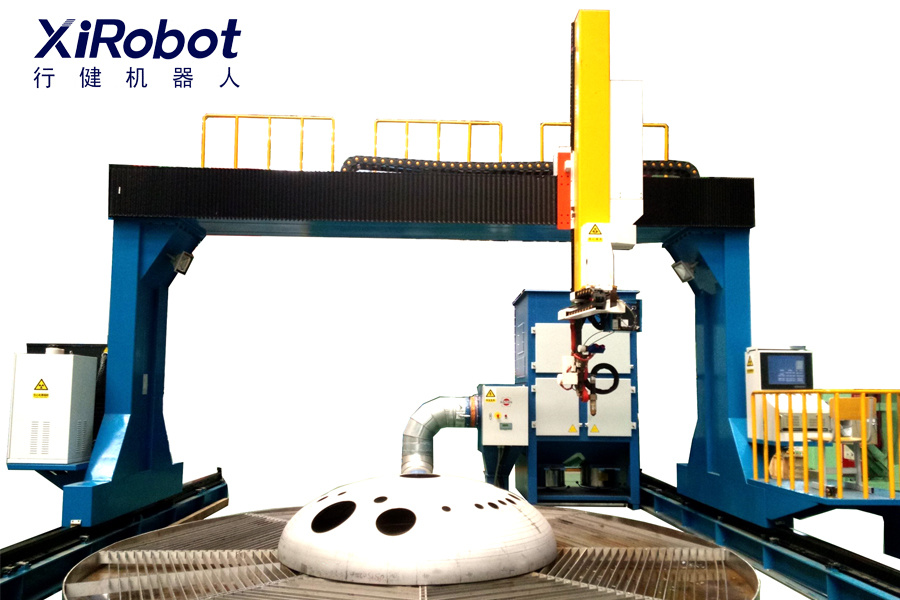

Automatic opening and cutting machine for head

This product is a multi axis laser vision positioning full-automatic cutting equipment for head and cylinder opening, which is suitable for high-precision and efficient one-time shaping cutting of various intersecting line holes on head and cylinder, especially for continuous positioning cutting of multiple holes on head and cylinder; It can be used in chemical equipment, industrial and civil boilers, pressure vessels, food and pharmaceutical equipment, shipbuilding and offshore engineering and other industries.

Magnetic crawling automatic tracking welding and cutting robot

This equipment adopts the wheel type magnetic crawling mode, and has the turning function, which can be remotely controlled. It can walk in an arc on the steel plate, automatically track the groove marking position (or automatically track the groove weld bead position), and cut the double-sided groove directly by double gun cutting (or complete multi-layer and multi-channel welding of various types of curved groove in space). It can be used for automatic cutting (or welding) in nuclear power, petrochemical, pressure vessel, shipbuilding and other industries.

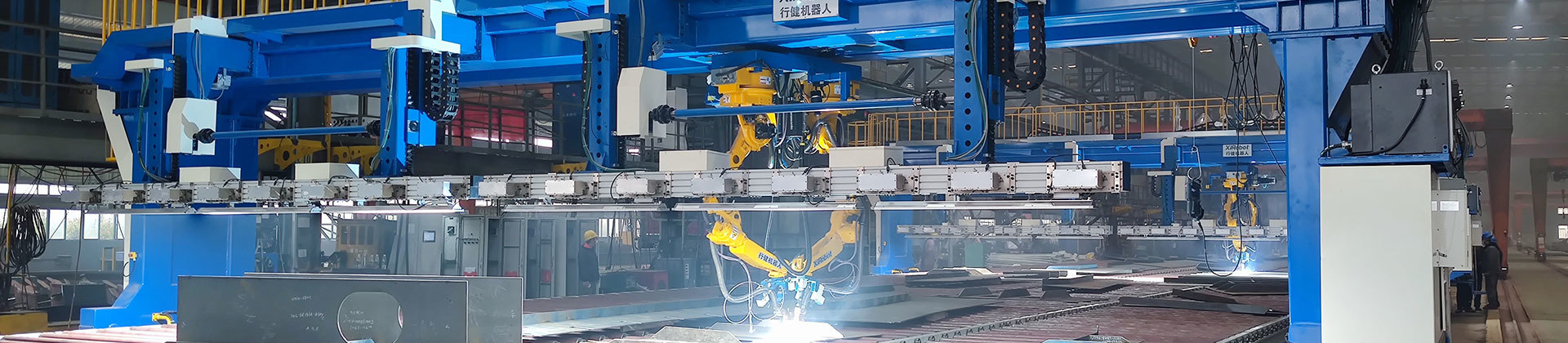

Curved panel measuring and marking groove cutting robot

This equipment is applicable to the measurement, scribing and secondary accurate cutting of ellipsoidal head plates of pressure vessels, spherical plates of spherical tanks and other types of curved steel plates. Realize the rapid, batch and high-precision intelligent production of curved steel plates with independent measurement, laser marking, visual real-time tracking, independent data correction, and simultaneous processing with two guns. It has been successfully applied to the intelligent production of large ellipsoidal head plate of AP1000 steel containment in China's third generation nuclear power plant, spherical plate of spherical storage tanks such as Lanshi Heavy Equipment Co., Ltd. and Luoyang First Construction Co., Ltd.

This equipment is mainly used for the welding of membrane wall tube panel accessories (channel steel) of coal-fired power plant boiler products. The front end of the welding gun is equipped with a visual tracking sensor to track the welding seam in real time and complete the welding of the attachment seam.