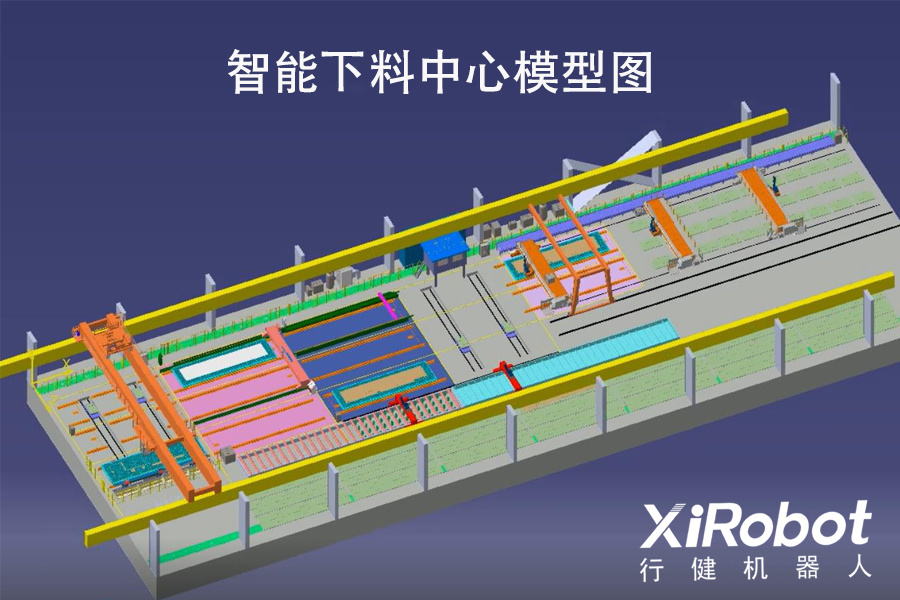

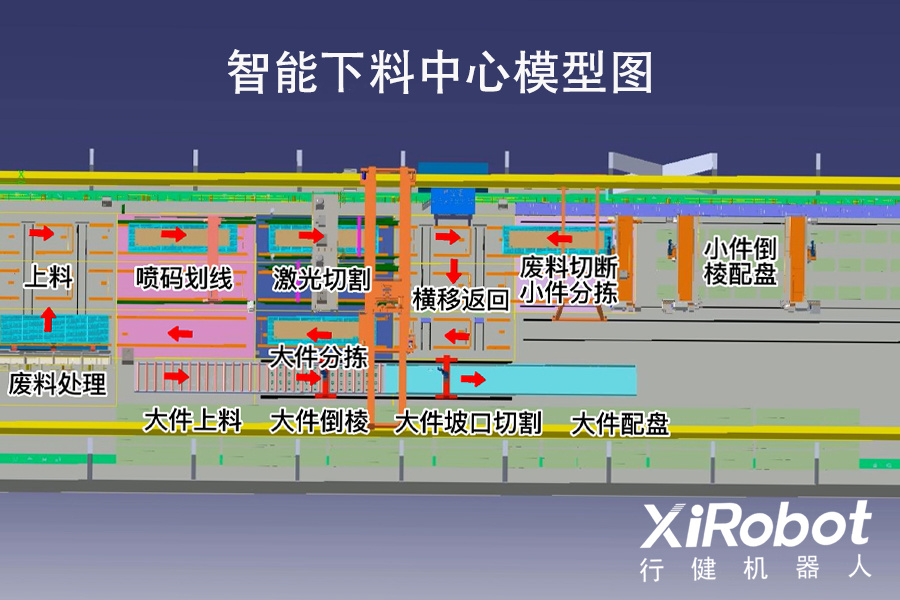

Intelligent blanking center

关键词:

1. Workpiece intelligent perception: use 3D laser vision to intelligently identify steel plate corners and edges; Using the composite vision composed of "3D panoramic vision+3D linear scanning vision" and combining nesting information to perceive and cut parts, intelligent identification and positioning of all parts processing links are realized, and the identification and positioning accuracy is higher; In the process, the design and implementation of 3D point cloud data acquisition system resistant to environmental interference are applied, including 3D point cloud data preprocessing algorithm, multi node 3D point cloud data splicing algorithm, and workpiece point cloud data and RGB image data fusion correction algorithm.

2. Extraction of processing technology: MES is generated by docking with shipbuilding platform software TRIBON/AM Process documents in gen format; The MES system automatically extracts the processing technology and corresponding process parameter information required for each link of the part processing from the ship design software TRIBON/AM.

3. Automatic cutting of waste materials: the existing nesting software has been upgraded and optimized, and fine vision technology has been used to achieve accurate search and positioning of the cutting position and effective cutting, so as to achieve reliable sorting of workpieces, with the sorting rate reaching 100%.

4. Dynamic grasp of workpiece: visual identification and positioning of parts and dynamic grasp algorithm during transportation.

5. Full autonomous programming: Complete the autonomous planning of the robot's trajectory, path and action according to the identified parts and the extracted process information, without manual programming. "Fool type" one click operation, greatly saving labor costs.

6. Rationalized layout: the overall layout is reasonable and compact, which improves the utilization rate of the production site and the overall production efficiency of the production line, and ensures the thoroughness of waste collection.

Range of processing workpieces(mm):≥12000×3000

| Station | name | technical parameter |

| Inkjet marking machine | Marking and printing form | Ink-jet |

| Scoring speed | >20m/min | |

| Laser cutting machine | Maximum positioning speed of cutter X and Y axes(m/min) | ≥40 |

| Maximum acceleration | ≥0.05G | |

| Maximum linkage positioning speed of Axis Y (m/min) | ≥50 | |

| Y-axis positioning accuracy |

X axis:0.5mm(overall length)) Y axis±0.05mm(overall length)) |

|

| Repeated positioning accuracy of Y-axis (mm/m) |

X axis:0.05mm/10m Y axis:0.03mm |

|

| Chamfering machine | Chamfering speed | ≤6000mm/min(Adjust according to material and process) |

| Pass rate | ≥98% |

Related Products

Get free product quotes