-

-

-

Products

-

-

-

-

Talent development

-

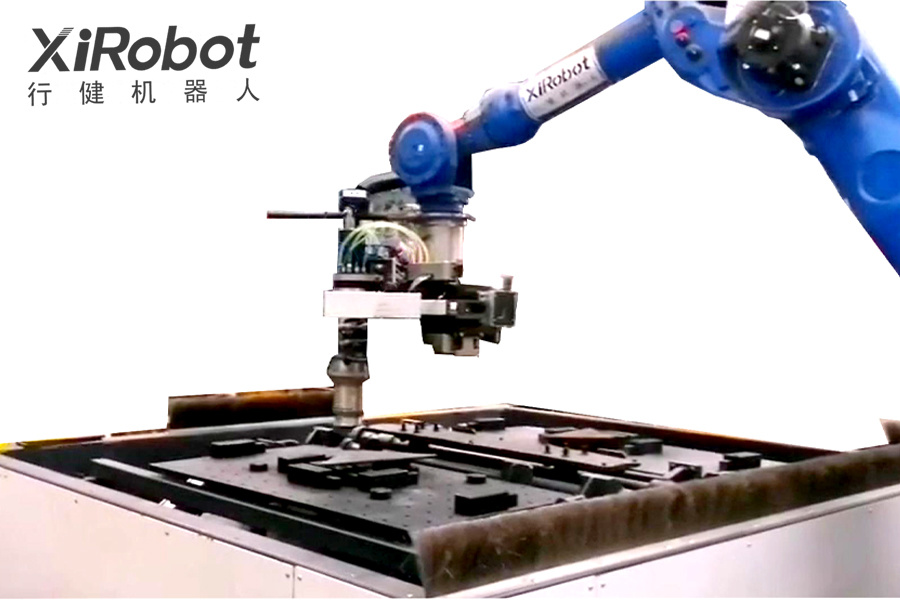

Intelligent chamfering unit for free edges of parts

关键词:

1. Intelligent perception of workpiece: rapid identification, positioning and grasping of parts, precise chamfering operation. The composite vision technology of "3D panorama+3D laser line scanning" is adopted, and the 3D point cloud data acquisition system is organically combined with the core processing algorithm to accurately identify the 3D scene AI.

2. Fully autonomous programming: no manual programming is required, and "fool type" one button operation is required. According to the identified parts and the extracted process information, the robot can complete the autonomous planning of the robot's trajectory, path and action posture, save labor costs and improve the working environment.

3. Flexible chamfering process: strong adaptability, good processing consistency, and guarantee the chamfering accuracy. Effective flexible chamfering tools and "active passive compliance" hybrid force control technology are used to improve processing flexibility and stability of processing force.

4. Character code recognition and matching: realize automatic process matching and automatic classification and matching of unordered parts. Based on the character code recognition and matching technology, configure the character recognition vision and algorithm, recognize the character code on the workpiece surface, and realize the production process record and quality traceability.

5. MES communication interface: realize information data transmission and equipment operation management.

| Project | Parameters |

| Equipment dimensions | 14m long × 8m wide × 4m high |

| Processing range | 2000mm long × 1000mm wide |

| Chamfer speed | 4000mm/min(Adjustable according to material and process) |

| Range of inner holes of machined parts | R≥35mm |

| Thickness range of machined parts | 6mm-48mm |

| Weight range of machined parts | 0.2-50kg |

| Repetitive positioning accuracy | ≤±0.2mm |

| Visual interface | support |

| historical data | support |

Related Products

Intelligent chamfering unit for free edges of parts

Get free product quotes

Contact Information

Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD

Address: No. 16 Lingyuan Road, National Robot Industrial Park, Jiujiang District, Wuhu City

Tel: +86-553-3865881

Harbin Xingjian Intelligent Robot Co., LTD

Address: Yard 8, Tongjiang Road, Jingkai District, Harbin City, Heilongjiang Province

Tel: +86-451-51789080

Official wechat

Official Douyin

Copyright © 2022 Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD