-

-

-

Products

-

-

-

-

Talent development

-

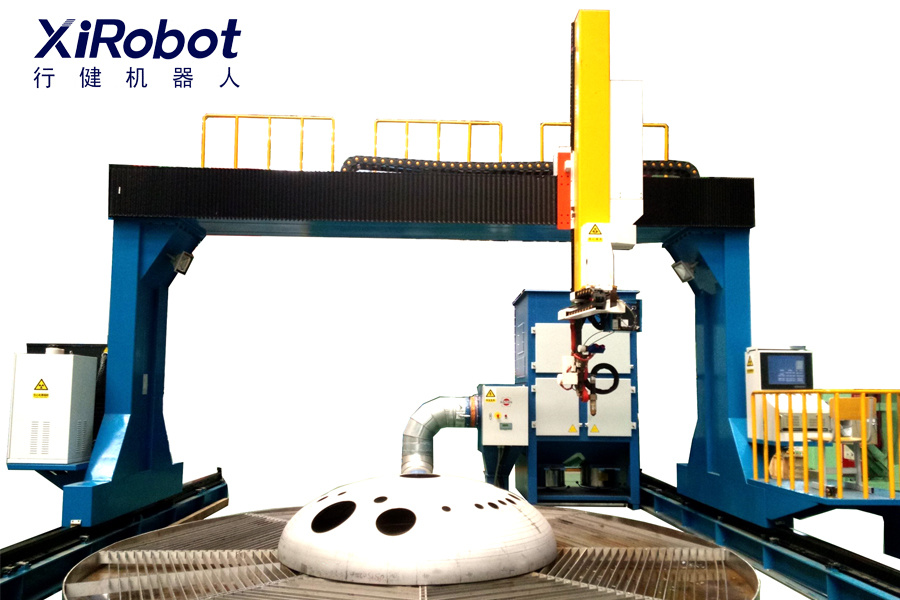

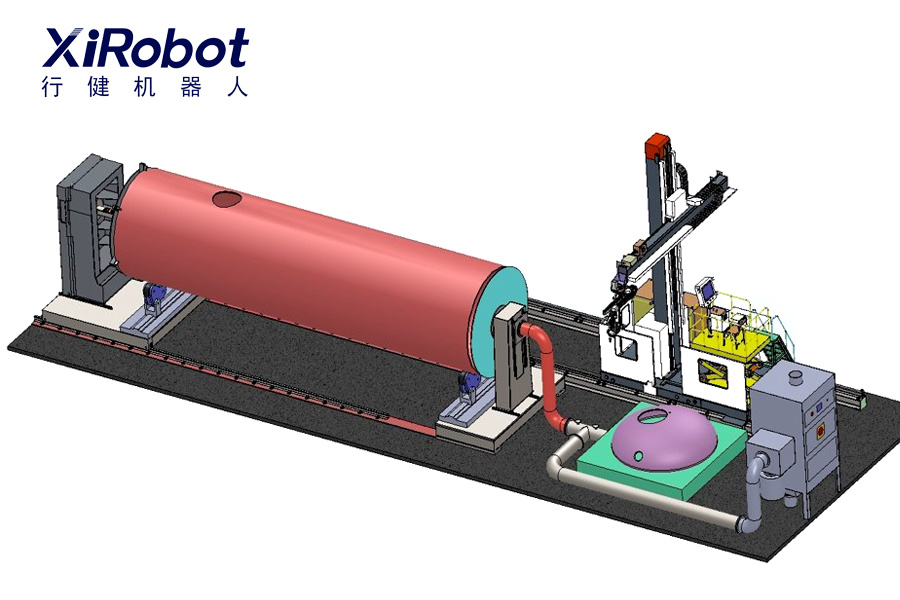

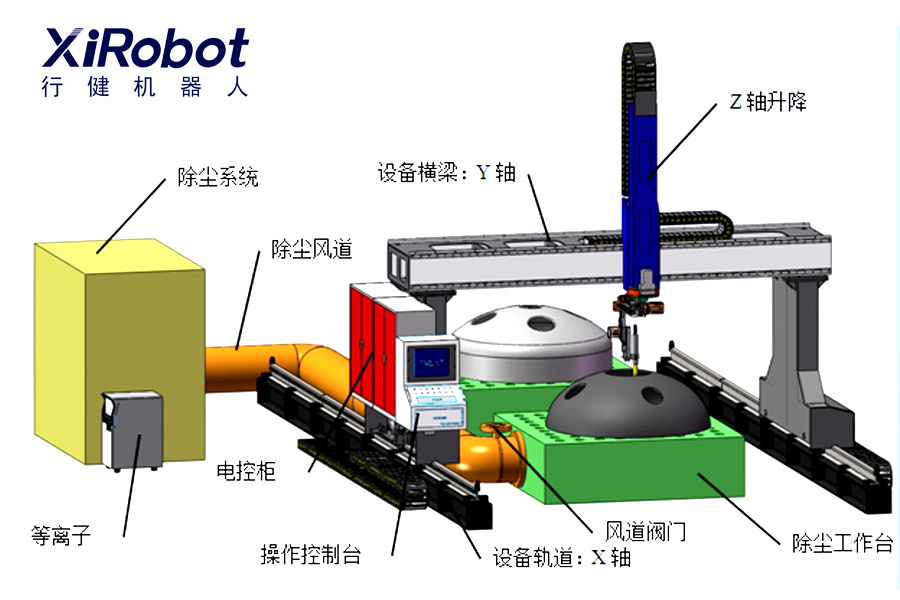

Automatic opening and cutting machine for head

关键词:

所属分类:

1. Parameterized drawing library programming software, multiple holes can be discharged at one time and cut continuously;

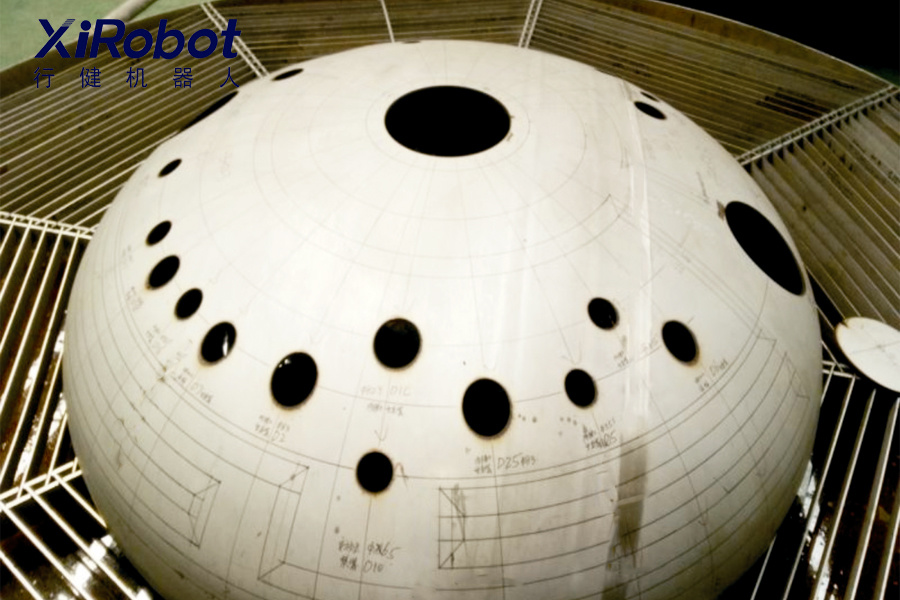

2. It can realize orthogonal, eccentric and oblique, eccentric and normal hole cutting of head;

3. Laser vision online tracking detection teaching, tracking and compensation during cutting;

4. Various compensation functions such as slotting, wall thickness, ovality and groove angle;

5. It has the cutting graphic simulation function to simulate and display the processing process.

| model | PHCR series | ||

| Host structure | Rectangular coordinate system (XYZ)+R radius axis+rotation axis (UV)+detection axis | ||

| trajectory |

3000~6000mm(Customizable) |

Rail length |

3000~15000mm(Customizable) |

| Length positioning accuracy |

0.1mm/1000mm |

Head type | Elliptical, dished, spherical head |

| Angle positioning accuracy |

0.1°/360° |

Head diameter |

500~6000mm(Customizable) |

| Airspeed |

≤12000mm/min(Settable) |

Head height |

≤2000mm(Customizable) |

| Cutting method | Flame/plasma/water jet cutting | Opening diameter |

50~1000mm |

| Cutting wall thickness |

flame: ≤200mm plasma: ≤40mm Water jet: ≤50mm |

Cutting speed |

0~3000mm/min |

| Groove angle | Fire ± 60 °, equal/water knife groove ± 45 ° | Cutting Limits | 0.9 times of head diameter at the edge of the opening |

| Groove form |

I、V、X、K |

Programming mode | Parametric programming software of system diagram library |

| Professional workbench | Customizable | Dust removal system | Optional |

Related Products

Intelligent chamfering unit for free edges of parts

Get free product quotes

Contact Information

Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD

Address: No. 16 Lingyuan Road, National Robot Industrial Park, Jiujiang District, Wuhu City

Tel: +86-553-3865881

Harbin Xingjian Intelligent Robot Co., LTD

Address: Yard 8, Tongjiang Road, Jingkai District, Harbin City, Heilongjiang Province

Tel: +86-451-51789080

Official wechat

Official Douyin

Copyright © 2022 Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD