-

-

-

Products

-

-

-

-

Talent development

-

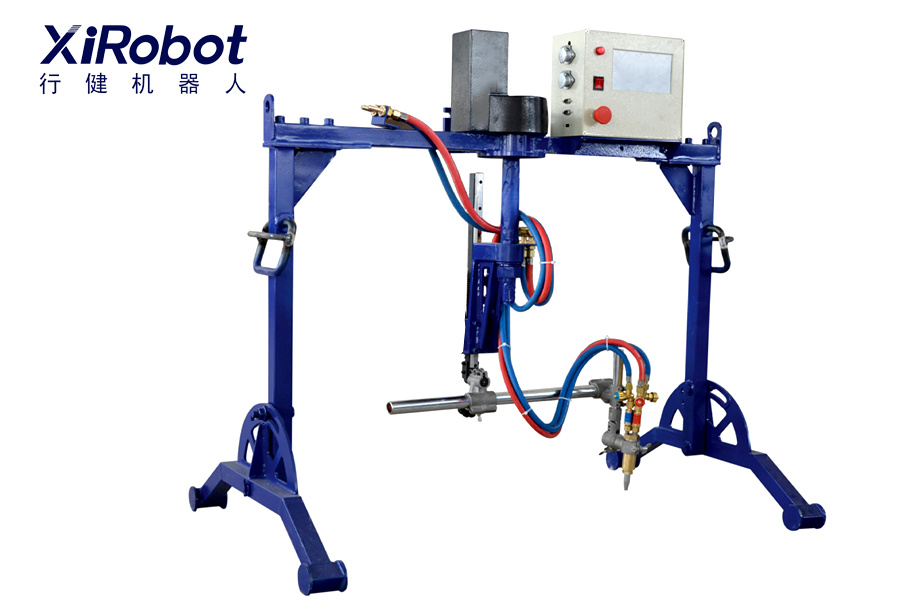

Portable saddle cutting machine

关键词:

1. Simple structure, small size, light weight, laser centering, portable and easy to use;

2. The control system uses motion control PLC as the core control device, which is stable and reliable;

3. Good human-computer interaction interface, simple operation of parameterized touch screen input and graphic prompts;

4. The control strategy combining theoretical algorithm and online teaching control is adopted to automatically correct the cutting path according to the actual workpiece size deviation, effectively eliminating the cutting error caused by the workpiece size error;

5. During the cutting process, workers can adjust the cutting speed in real time according to experience to achieve the ideal cutting quality.

| model | MAGB-1000 |

| Opening diameter (straight) | φ100~1000mm |

| Saddle drop | ≤150mm |

| Groove angle | ±45° |

| Cutting thickness | ≤200mm |

| weight | 60Kg |

Related Products

Intelligent chamfering unit for free edges of parts

Get free product quotes

Contact Information

Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD

Address: No. 16 Lingyuan Road, National Robot Industrial Park, Jiujiang District, Wuhu City

Tel: +86-553-3865881

Harbin Xingjian Intelligent Robot Co., LTD

Address: Yard 8, Tongjiang Road, Jingkai District, Harbin City, Heilongjiang Province

Tel: +86-451-51789080

Official wechat

Official Douyin

Copyright © 2022 Anhui Xingjian Intelligent Manufacturing Equipment Co., LTD